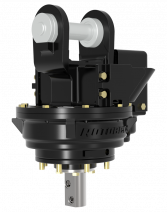

Waste Collection Grapple

This lightweight grapple is ideal on self-loaders and can be used to pick up every material imaginable for unbeatable results.

The very popular Waste Collection Grapple offers superior performance.

This trash and debris grapple is commonly used on municipal vehicles for waste pickup and storm clean up. They are available with both high and low pressure cylinders and in a variety of sizes, allowing for installation on every type of loader or excavator. If you are in need of a do-everything attachment, there is a Rotobec waste collection grapple ready for the challenge.

02 Features

We’re called ROTO-BEC for a reason.

We are well-known for our innovation and development of the most advanced continuous 360° rotators. Our rotators are without a doubt the longest lasting ever made. They offer cost-effective maintenance due to easily accessible greasing points, a durable motor, and a fully supported pinion gear allowing them to go further and protect your investment. All of our dangle style rotators are fully sealed, allowing them to be fully submerged in up to 15 feet of water with the standard 360° rotator. We are committed to delivering the most reliable rotators on the market, no matter where you are in the world. Why settle for anything but the best?

The Smallest Details Matter Most.

Rotobec is recognized worldwide for its innovation. All of our grapples are made with only the highest quality steel and components to provide you with the best and most durable products out there. Combined with our exceptional workmanship, we ensure the longevity of your attachment with our top engineered designs and meticulous quality control. We have put our heart and soul in every detail to bring you the best and highest performing attachments in the industry.

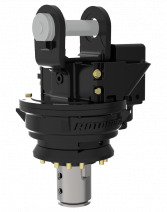

The Finest Design For Superior Performance.

There is no place for the weak in waste handling! The threat of damaged cylinders is a common and costly problem that can quickly bring your entire operation to a grinding halt. In order to protect your most precious asset, we have designed a cylinder that has revolutionized the waste industry. Rotobec provides you with a cylinder that is better protected and more durable than any other option on the market. Want less downtime and less damaged cylinders? Try our famous cylinders for yourself. You will never look back.